Home | Services: Design

Design and prototyping are services offered in a quick and highly detail-oriented way. Each product is followed by the technical department of Tagliapietra s.r.l. that with the latest generation software is able to accept and process every challenge proposed by the customers. Being able to develop a physical prototype allows Tagliapietra s.r.l. to optimize the production times in order to perform preliminary tests, providing the customer with a product that complies with the required specifications.

Working with Tagliapietra s.r.l. means having the guarantee of a quality product. The automation of production processes enables the company to offer an innovative service.

Feasibility

analysis

Co-design of the product

with the customer

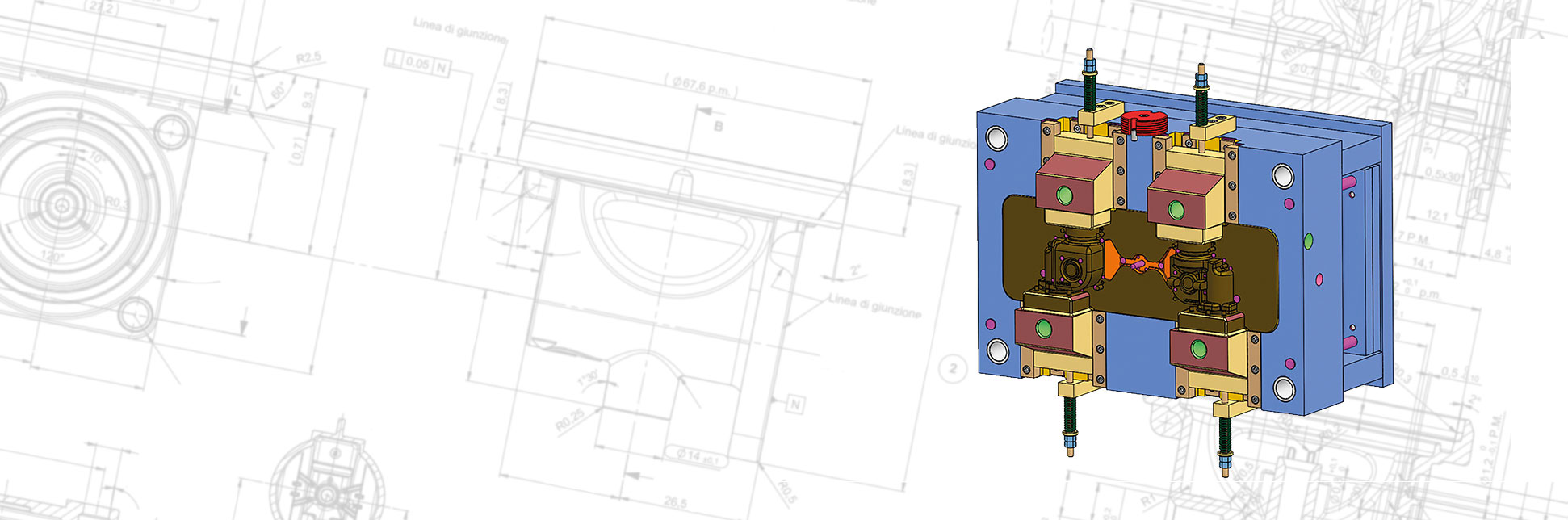

Definition of models

for moulding

Realization of prototypes

with different materials and technologies according to the customer’ needs

Equipment design

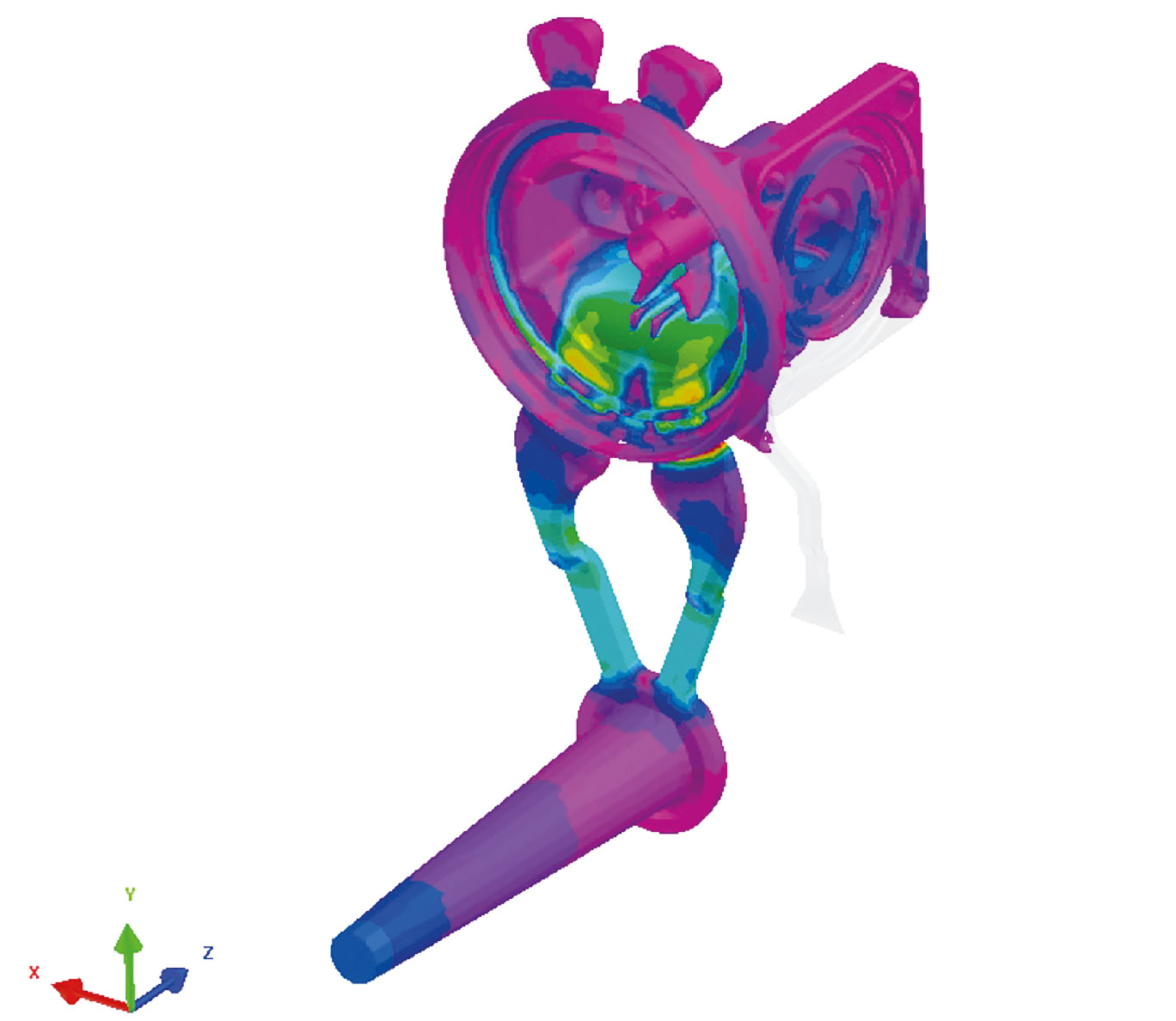

Mould filling

simulation

Verification of equipment

by sampling

Supply of PPAP documentation

Confidentiality

Mould

filling simulation

© Copyright Tagliapietra s.r.l. - C.F. / Reg.Imp. / P.IVA 01881770240 - R.E.A. 191018 - Cap. Sociale: 20.000,00€ | Privacy & cookies | Credits: Stargraphic Adv