Home | Services: Other productions

Tagliapietra s.r.l.:

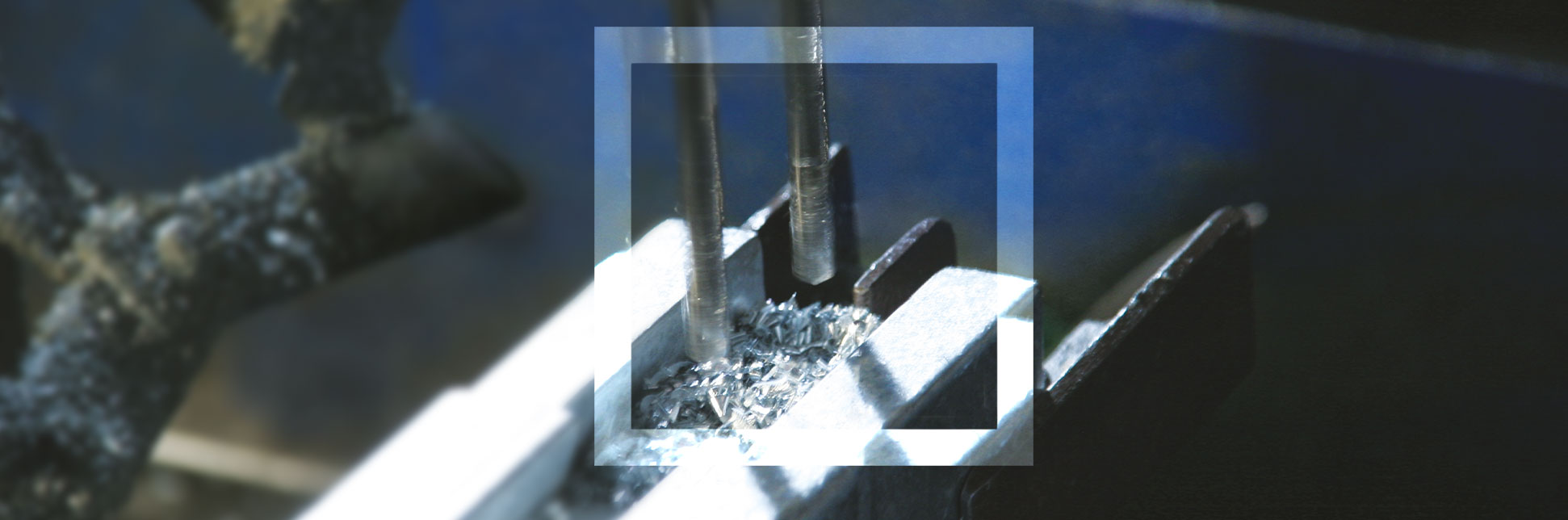

other types of processing

Machine Park,

Production,

Other processes.

Home | Services: Other productions

Tagliapietra s.r.l.:

other types of processing

Machine Park,

Production,

Other processes.

Home | Services: Other productions